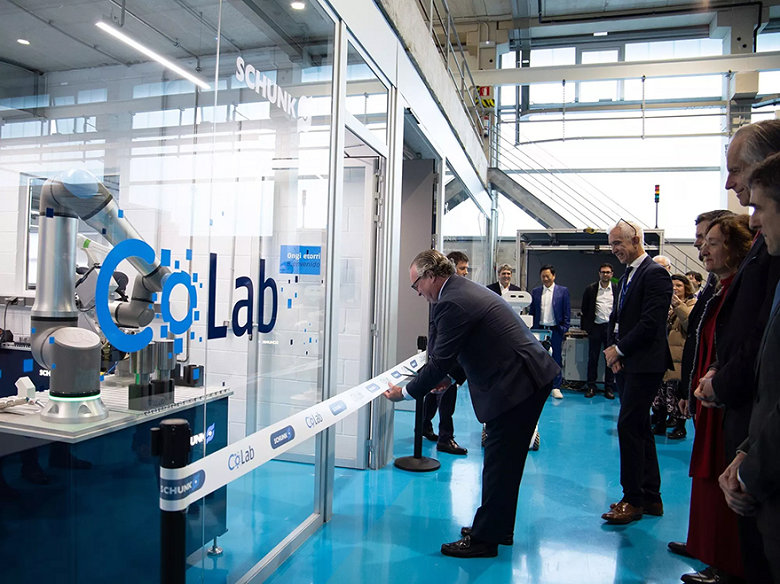

Schunk launches new robotics applications centre

This is a further step in the company’s aim to automate its customers' processes in a personalised way.

The German company Schunk, which specialises in equipping production systems, has opened a robotics applications centre in Éibar (Guipúzcoa). The objective of this laboratory will be to help implement its customers’ automation processes in a way that is customised and close to reality. This step makes it possible to tackle the actual start of automation without any risk and with more efficient production processes.

With this hub and a similar one opened in Poland, the company now has 15 CoLabs, as it calls them, and with which it wants to expand the automation expertise at its work centres around the world. In the case of the laboratory the company opened in Éibar in December, it has partners like ABB, Kuka and Universal Robots which are helping it to set new benchmarks for automated on-site solutions.

Competitiveness and efficiency

For Schunk, automation is a crucial process for a company to remain competitive and ensure that its production processes are efficient. At its robotics application centres the company supports its customers as they carry out their tasks and, based on observation and analysis, it develops a series of recommendations designed to increase productivity.

Schunk's Chief Operating Officer and Chief Safety Officer, Johannes Ketter, says that with the new CoLabs “we are not only expanding our global expertise, but also strengthening our position as a reliable partner in the automation industry,” adding, “This is a decisive step towards making automation as simple and efficient as possible for our customers. We firmly believe that the best way to create innovation is through collaborative partnerships on a level playing field.”

Specific requirements

In addition to bringing the company closer to its customers around the world, expanding its network of robotics applications helps it to offer individual support and respond quickly to specific customer requirements. CoLabs thus become a very important element for planning and implementing industrial automation and robotics applications.

The service offered by these centres can benefit automation novices and experienced professionals alike, with input ranging from validation to specific support from application engineers. In addition, planned applications can be tested under real-life conditions prior to purchase, minimising risk and maximising results.

Photo: Schunk