Domino has branches in Madrid, with a fully equipped showroom, and in Barcelona, where it offers personalised demonstrations and technical training.

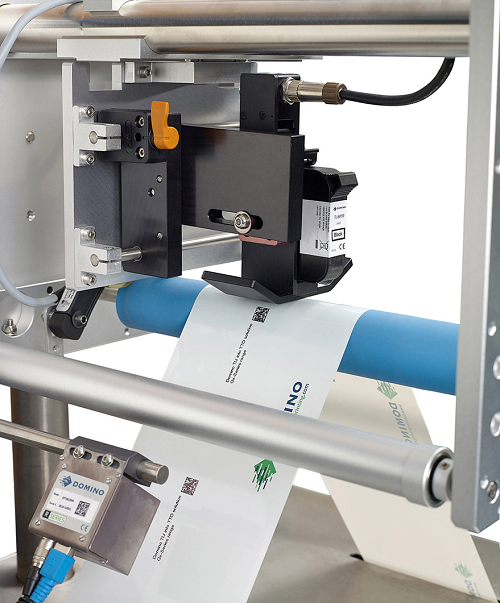

Domino Printing Sciences was founded in the UK in 1978 and specialises in coding, marking, labelling and printing technology solutions. It has a comprehensive portfolio of primary, secondary and tertiary packaging solutions designed to meet the compliance and productivity requirements of manufacturers in all industries. It uses innovative inkjet, laser, label print and apply, and thermal transfer printing equipment.

Domino Amjet Ibérica, a subsidiary of the group, celebrates its 35th anniversary in Spain this year. Ever since 1990, the company has accompanied the technological transformation of industries such as food, beverages, pharmaceuticals and cosmetics. It boasts an ability to anticipate market needs and offer comprehensive, customised and sustainable solutions, boasting 20% growth in its last tax year, a feat it expects to repeat this year.

How has coding, marking and labelling evolved over the past 35 years?

In over thirty years, coding, marking and labelling have evolved from mechanical processes to key technological solutions. We have transitioned from classic linear barcodes, which only provided basic information, to 2D codes such as QR and Data Matrix, which are able to include complete data: batch number, expiry date, allergens, composition, traceability and even links to digital content. All this responds to a clear need: to gain efficiency, control and transparency in the supply chain. This change has been driven by both regulatory developments and technological progress. At Domino, we're committed to high-resolution inkjet, CO₂ laser, fibre and UV, thermal transfer and smart labelling systems — all with one goal in mind: to code more accurately, faster and more sustainably, even in the most demanding environments. And in this evolution, automation and connectivity have been key to integrating these solutions smoothly and efficiently into production lines. Sustainability has also come to the fore. Companies are committed to reducing emissions and are looking for technologies aligned with that goal. For this reason, and in line with our commitment to CSR, we work with plant-based inks, more efficient ribbons and systems that reduce waste and downtime. Coding is no longer just a part of the process; it is a strategic tool to innovate, become more competitive and build a more responsible industry.

How has Domino helped Spanish industry in its technological transformation?

We have been a great ally in the Spanish industry's transition towards digitalisation and supply chain automation. Our technology has enabled hundreds of companies to adapt to new standards of traceability, coding and sustainability, especially through solutions that integrate real-time variable data, 2D code printing and international regulatory compliance. In fact, we are the only certified GS1 technology partner in Spain, and beyond coding and marking equipment, we have also developed intelligent tools such as Domino Automation, which facilitates system integration and improves operational efficiency. We have also opted for artificial vision solutions and control software that enable us to validate each code and avoid errors before they affect production. These innovations, together with our technical support network and a strategy focused on customisation, do as a consequence allow us to say that Domino has actively contributed to the Spanish companies that have placed their trust in us, in order to move towards Industry 4.0, and combining precision, connectivity and sustainability in their production lines.

How important is Spain for the company’s strategy?

Spain is a strategic market for the group, as demonstrated by its steady growth over the last 35 years. In the last financial year, the Spanish subsidiary recorded an increase of over 20% in its results and expects to increase them by another 20% this year. This is evidence of the degree of maturity achieved by the company, as well as its leading role in the transformation of the industry and its commitment to continue to drive manufacturing with high-value solutions, as well as applying our major premise: "Do more." It is a commitment to our customers that drives us to go the extra mile and to always be at the forefront in order to offer them the best comprehensive solutions. That is why we have branches in Madrid, where we have a fully equipped showroom, and in Barcelona, both supported by a highly qualified and committed team, and expanding in commercial, technical and after-sales areas. It is also important to note that the Spanish market stands out for its dynamism, especially in industries such as agri-food, beverages, pharmaceuticals, etc., where the need for advanced coding and traceability technologies continues to grow. All these aspects have therefore consolidated Spain as a strategic point of operations for the group in southern Europe.

What are the most outstanding projects you have carried out in Spain?

At Domino, we focus our main investments on developing innovative, end-to-end coding, marking, labelling and traceability solutions to strengthen our infrastructure, improve customer experience and get closer and closer to meeting 100% of our customers' needs. One of the most important initiatives was the opening in 2023 of our new offices in the Sant Cugat del Vallès Business Park (Barcelona), designed to offer tailored demonstrations, technical training and a more agile service to current and potential customers. We are also constantly strengthening our technical, commercial and after-sales capabilities, thereby consolidating our growth in strategic markets. Moreover, we actively participate in the main trade fairs for the industry, such as Empack, maintaining direct contact with manufacturing challenges, detecting new trends and adapting our offer to the real demands of the national market. This permanent presence strengthens our technological leadership and enables an ongoing dialogue with customers in order to offer them individual, effective solutions aligned with their objectives.

How many employees do you have in Spain?

At Domino, the team is everything. More than 80 professionals in Spain work with a high level of commitment and specialisation to be close to the client and provide real solutions. Their focus in areas such as technical support, engineering, sales and customer service are key to maintaining an agile, close and quality service. The company's growth goes hand in hand with its human value. We are including new profiles, mainly for technical and commercial staff who share the same commitment: to drive innovation and respond to the real challenges of important industries such as pharmaceuticals, food, beverages and cosmetics.

What are the next challenges the market poses?

The market demands that we stay one step ahead on three key fronts: sustainability, safety and automation. On the one hand, companies need solutions that reduce their environmental impact, and that means developing more efficient technologies that consume less, generate less waste and comply with increasingly demanding regulations. That is what we are fully focused on. On the other hand, the fight against counterfeiting is another urgent challenge, especially in industries such as pharmaceuticals, where traceability saves lives. That is why we are a GS1 technology partner and develop and promote solutions that guarantee the authenticity and traceability of each product, from origin to point of sale, with full traceability and in compliance with international standards. Finally, the third challenge is automation, which is no longer a competitive advantage, but a requirement. Businesses are looking for faster, more accurate and connected processes. That's why at Domino, we develop solutions that integrate coding, machine vision, software and connectivity to turn production lines into intelligent, flexible systems that meet new demands.

Photos: Domino