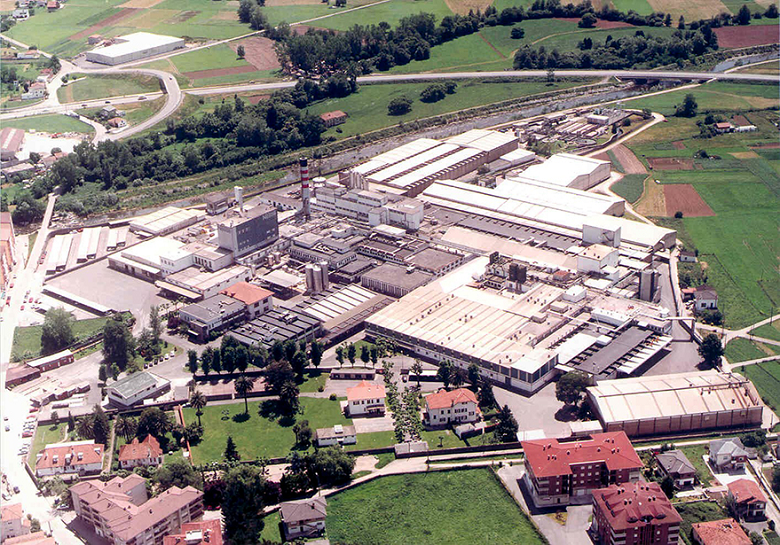

Nestlé drives Cantabria plant towards sustainable future

The Swiss company has invested nearly €75 million in these facilities since 2020.

The Nestlé factory in La Penilla de Cayón (Cantabria) is consolidating its position as an industrial benchmark in Spain thanks to an investment of around €75 million since 2020. These resources have been allocated to enhancing the digitalisation, automation and sustainability of its processes, with the aim of adapting to the current and future demands of the food industry.

Investment in sustainability is nothing new at this factory, which currently produces chocolate, confectionery, soluble cocoa, infant cereals and wafers for pastries. In 1966, it launched its first wastewater treatment plant, ahead of what became a legal requirement 20 years later. €1.8 million has been allocated to protecting river water over the last five years.

Continuous water reuse

Last September, a group of cooling towers was commissioned, adding to those installed in 2022. Their purpose is to facilitate the continuous reuse of water, which, after being used in industrial activity, undergoes an evaporative cooling process and remains in a closed circuit. This measure has reduced water consumption by around 600,000 cubic metres, which is equivalent to filling 240 Olympic swimming pools.

To complete its environmental measures, the Cantabrian plant has a zero waste to landfill system, which consists of minimising waste generation and promoting reuse, recycling and recovery. All the electricity that powers the centre does in addition come from renewable sources.

Biomass boiler

In another example of circularity, the energy source used in the cocoa bean roasting process at this factory is also renewable. In 2022, a biomass boiler was commissioned that uses the husks obtained from the cocoa bean roasting process as biofuel for steam production. The biomass boiler also uses wood chips certified as sustainable at source, and in just three years it has prevented the emission of around 6,000 tonnes of CO2 into the atmosphere.

In 2023, another facility was launched: a heat pump that harnesses residual energy from the cooling plant. This heat, which is not allowed to escape, is used to heat the water used in both production processes and plant air conditioning. This has saved another 12,000 cubic metres of water and prevented the emission of 2,500 tonnes of CO2 per year.

Photo: Nestlé